US/EU Hydraulic Fracturing - Bakken Safety Tour 2016

US/EU Cooperation on Workplace Safety and Health →

An action item from the 2015 Joint US/EU Conference in Fort Worth, Texas, on Health and Safety at Work was the Hydraulic Fracturing – Bakken Safety Tour 2016, both a conference and a site visit, showcased Bakken Oilfield hydraulic fracturing safety practices for labor, government and industry representatives of energy sectors of the United States and the European Union.

MonDaks Safety (STEPS) Network →

Conference Program

To view from a desktop computer please click on the flipbook below.

Presentations

JAMES WARD, DALE HOPWOOD

Waste Water Disposal and Abandonment Philosophy

TONY ALMOND

Environmental Regulation and Planning Conditions for Onshore Oil and Gas well sites in the UK

MARK QUINT

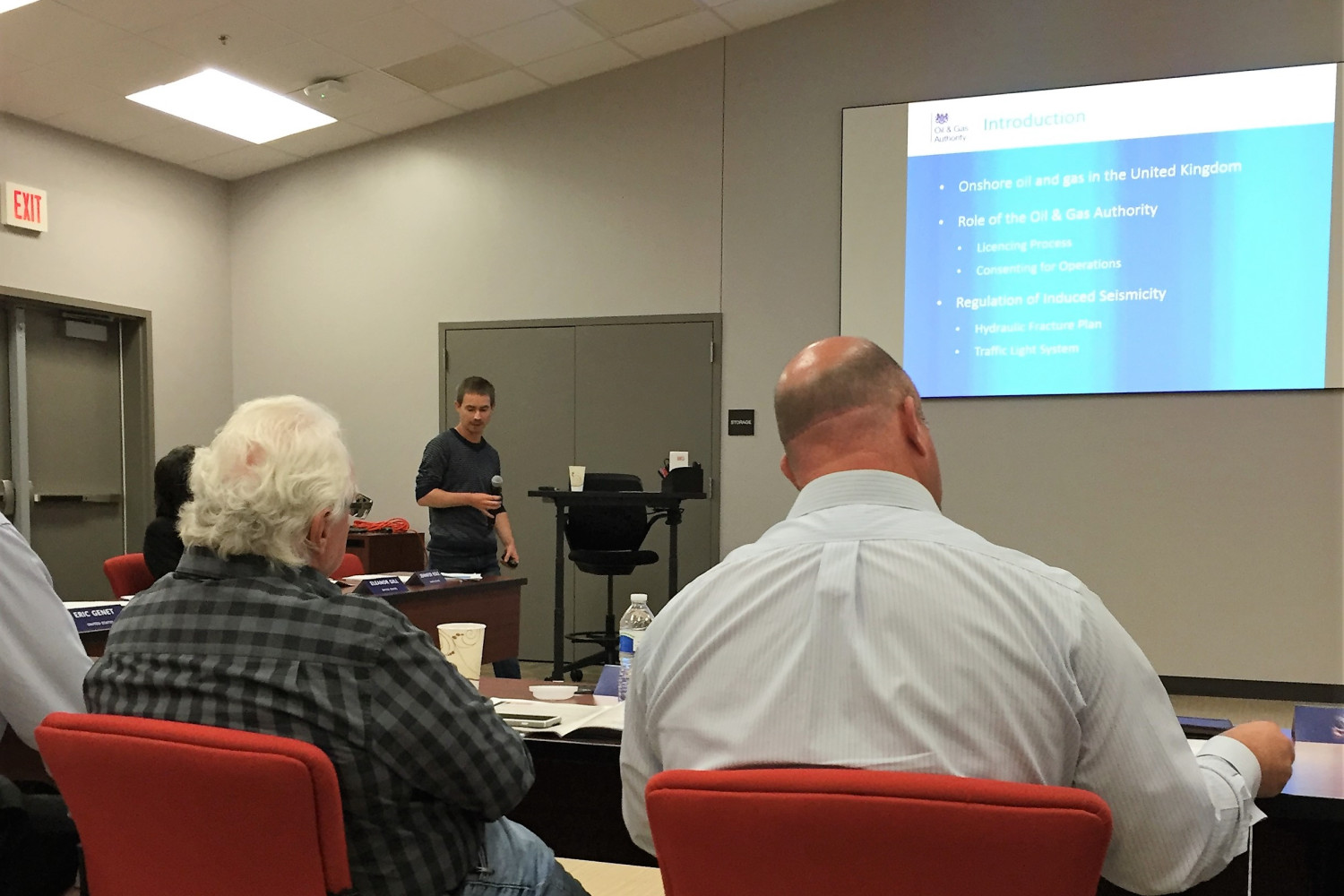

Role of the Oil & Gas Authority in Licensing, Consents and the Regulation of Induced Seismicity

LYNN HELMS

ND Regulations, Planning and Permissions

PAUL BRADLEY, CRAIG NORMAN

Health and Safety Regulatory Regime in the UK

KYLA RETZER

Epidemiology Perspective

JOHN SNAWDER

NIOSH Field Studies, Exposure Assessment, Silica Controls and Gauging and Thiefing

ERIC BROOKS

Incidents and Lessons Learned

MONTE BESLER

Engineered Safety and Environmental Aspects of Well Construction and Fracturing Design

RON GUSEK

Vorteq Manifold Trailer and The Quiet Fleet

PAUL ABLE

Environmental Responsibility and Lean Innovations

JOAN SMITH

Training in Support of Career Paths in Upstream Onshore Oil and Gas E&P

RICK INGRAM

OSHA-NIOSH-National STEPS Network Alliance

Conference General Information

What is Hydraulic Fracturing?

Hydraulic fracturing and horizontal drilling are safely unlocking vast U.S. reserves of oil and natural gas found in shale and other tight-rock formations. Developing energy from shale is an advanced process that uses the latest drilling technologies and equipment. As for what fracking means to the United States – the answers, are security, economic growth and jobs, jobs, jobs. The U.S. Energy Information Administration (EIA) details how surging domestic oil production is narrowing net petroleum imports – from 60 percent of what the United States used in 2005 to 45 percent in 2011. This change is driven by production from unconventional reserves using fracking and horizontal drilling.

Read a Primer for detailed information about hydraulic fracturing.

FracFocus: The typical fracturing fluid is approximately 90% water and 9.5% sand, with the remainder being additives that aid well production. The oil and natural gas industry has led the way in its support for public information about fracturing fluids; industry voluntarily discloses the contents of its fluids at FracFocus.org, which is run by the Groundwater Protection Council and the Interstate Oil and Gas Compact Commission. FracFocus provides a public database that can be searched by well or well location so that concerned individuals can easily identify the constituents used to fracture specific wells.

As of the summer of 2015, over 900 companies have provided information on more than 100,000 wells and that number increases every day.

Industry Standards Addressing Hydraulic Fracturing

American Petroleum Institute (API) is the world’s leading standard-developing organization for the oil and natural gas industry. This infographic is an overview of industry guidance documents and best practices supporting hydraulic fracturing operations.

Hydraulic fracturing is a proven technology used safely for more than 60 years in more than a million wells.

It uses water pressure to create fissures in deep underground shale formations that allow oil and natural gas to flow.

First used in the U.S. in 1947, the technology has been continuously improved upon since that time.

Recent innovations combining this technology with horizontal drilling in shale formations has unlocked vast new supplies of natural gas, allowing the nation to get to the energy it needs today, and transforming our energy future.

Step Change in Safety

Step Change in Safety is a not-for-profit, member-led organization which aims to make the UK the safest oil province in the world to work in. Safety cannot be left to C-suite executives alone. It requires collaboration from everyone. This is why Step Change brings together operators and contractors, trade unions, regulators and the onshore and offshore workforce. Through the four Step Change Steering Groups, work-groups and growing support team, Step Change will work relentlessly to raise safety standards, share good practice and communicate facts so that no-one becomes complacent about staying safe.

What is a Safety Case?

A safety case is a document produced by the operator of a facility which: Identifies the hazards and risks, describes how the risks are controlled, and describes the safety management system in place to ensure the controls are effectively and consistently applied.

Safety cases must be produced by the operator of a installation: The principle here is that those who create the risk must manage it. It is the operators' job to assess their processes, procedures and systems to identify and evaluate risks and implement the appropriate controls, because the operator has the greatest in-depth knowledge of their installation.

The safety case must identify the safety critical aspects of the facility, both technical and managerial: Analysis of disasters almost always show a combination of technical and managerial flaws which have led to the event occurring.

Appropriate performance standards must be defined for the operation of the safety critical aspects: A 'performance standard' is a standard, established by the operator, of the performance required of a system, item of equipment, person or procedure which is used as a basis for managing the risk of a major accident event.

The workforce must be involved: Workforce involvement is necessary so they know what happens in practice and why. This makes it more likely that they do the right thing because they know why, rather than relying on a 'rules-based' culture.

The safety case is produced in the knowledge that it will be scrutinized by a competent and independent regulator

NOPSEMA assesses safety cases and 'accepts' a safety case if it is satisfied that the arrangements set out in the document demonstrate that the risks will be reduced to as low as is reasonably practicable (ALARP). Following this 'accepted' safety case, NOPSEMA will conduct inspections in relation to facilities to monitor the operator's application of the safety cases in practice.